Cotton swabs are a common tool in our daily lives, but do you know how they are made? This blog will introduce the various essential pieces of equipment used in a cotton swab production line.

1. Cotton Swab Stick Manufacturing Machines

The stick is a crucial component of a cotton swab, and different types of sticks require different manufacturing machines:

- Paper Stick Manufacturing Machine: This machine is used for making paper sticks by rolling paper and applying adhesive for strength.

- Plastic Stick Extruder: Utilizes PP or PS materials to produce plastic sticks through an extrusion process.

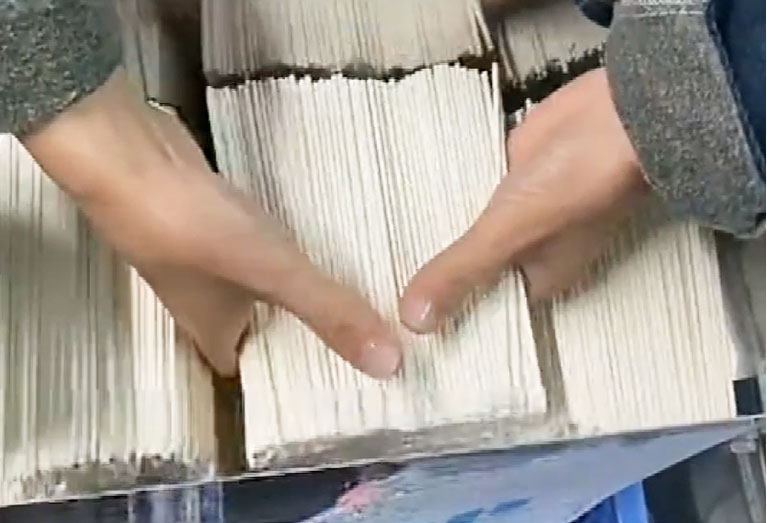

- Bamboo Stick Processing Machine: Handles the cutting, polishing, and finishing of bamboo sticks to ensure they are smooth and sturdy.

2. Stick Cutting Machine

- Automatic Cutting Machine: Used to cut long rods of stick material into suitable lengths for cotton swab sticks, ensuring each stick is of consistent length.

3. Cotton Processing Equipment

- Cotton Opener: Loosens cotton into a fluffy fiber state, making it easier to combine with the sticks.

- Cotton Cleaner: Removes impurities from the cotton, such as grass seeds and dust, ensuring the hygiene and quality of the cotton swabs.

- Cotton Carding Machine: Aligns the fibers uniformly, preparing them for rolling.

4. Cotton Swab Manufacturing Machines

- Cotton Rolling Machine: Rolls the carded cotton into strips and cuts them to the appropriate length.

- Stick Inserting Machine: Inserts the cut cotton strips onto the sticks, forming the basic shape of the cotton swab.

- Adhesive Application Machine: Applies glue to the sticks to secure the cotton strips in place.

5. Drying Equipment

- Drying Oven: Used to dry the produced cotton swabs, removing moisture and improving product quality. Specific types of drying machines, such as microwave drying ovens, can achieve cleaner production and higher product quality with automated control.

6. Quality Inspection Equipment

- Automatic Inspection Machine: Checks the length, strength, and hygiene of the cotton swabs, ensuring that each batch meets production standards.

7. Sterilization Equipment

- Sterilization Equipment: Used to sterilize the cotton swabs, ensuring they meet hygiene standards.

8. Packaging Equipment

- Cotton Swab Packaging Machine: Automatically counts, bags, boxes, and seals the cotton swabs.

- Sealing Machine: Used for sealing packages, especially when manual bagging is involved.

- Labeling Machine: Applies labels to the packaging, indicating product information.

- Fully Automatic Packaging Machine: Eliminates the need for manual operations, significantly increasing production efficiency.

9. Auxiliary Equipment

- Conveyor Belts: Transport cotton swabs between different production stages.

- Air Compressor: Provides the necessary air supply for equipment operation.

- Waste Handling System: Collects and processes waste generated during production.

10. Control System

Modern cotton swab production lines are typically equipped with advanced control systems to monitor and control various stages of the production process, ensuring efficient and stable production.

11. Cleaning and Maintenance Equipment

Used for the regular cleaning and maintenance of cotton swab production equipment, ensuring normal operation and extending the equipment’s lifespan.

Conclusion

The equipment in a cotton swab production line is diverse, covering all stages from raw material processing to product packaging. Selecting and configuring the appropriate equipment according to specific production needs is key to ensuring high-quality cotton swab production. Understanding these machines and their functions helps to better grasp the entire process, improving both production efficiency and product quality.

We hope this article provides you with a deeper understanding of cotton swab production. If you have any questions or need more information, feel free to contact us.

Liling Xiao

Senior Sales Negotiation Expert

Jouyou Technology

sales@jouyoutech.com

WhatsApp: +86 134 5924 6186

Explore our website: jouyoutech.com